Typical Applications of Led High Mast Light, High Mast Lighting Systems

1816Typical Applications of Led High Mast Light, High Mast Lighting Systems

View details

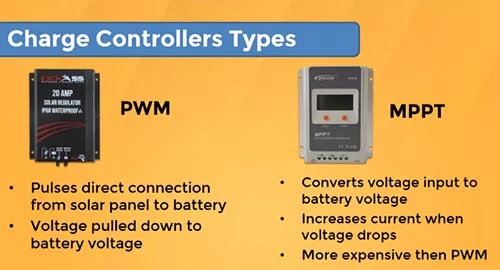

We have learned about the features of both controllers (PWM & MPPT) in previous chapters. We well noted that PWM does not convert extra voltage into currents, which results in low power conversion rates. In other words, PWM doesn’t transfer all energy that is collected by solar panels to batteries, but MPPT is always tracking the maximum power point from the panels and adjusting its currents and voltage accordingly so that it can transfer all energy collected by solar panel to battery.

PWM vs. MPPT A concrete example will explain this clearly:

The basic physical formula:

Power (watts) = V (Volts) x I (Amps)

If we use a nominal 12V, 100W solar panel to charge a 12V battery system, the actual Vmp is 17V, and we can calculate its current output:

I = Power / V

I = 100 / 17 = 5.88 amps

Now we know the panel output is 17V and 5.88A.

Scenario 1: The photovoltaic system is with PWM solar charge controller.

PWM will drag the voltage down to battery charging voltage – approximate 14V. After going through the PWM, the solar energy only remains 14V and 5.88A.

That is:

P = V x I = 14 x 5.88 = 82.32 W

Scenario 2: The photovoltaic system is with the MPPT solar charge controller.

The MPPT not only drags the voltage down to 14V, but also increases the current, so that the power almost equals to power out.

So, if the voltage decreases by 17/14 = 1.21

Then the current to battery increases by 1.21, we get

5.88 x 1.21 = 7.11A

Total power out

P = 14 x 7.11 = 99.54 W

In this example, the power wasted by PWM is

99.54 – 82.32 = 17.22W

Almost 20% energy was not converted to battery chemical energy. If we consider the scenario in a large solar array, the loss could be tremendous.

So, it’s better to use MPPT for large solar array.

a) High conversion efficiency

If your photovoltaic system comes with a large solar array, MPPT would be the best choice to boost the solar energy conversion, especially in cold weather, since the panel voltage will rise as the temperature drops. The MPPT conversion rate could rise from 20% to 40%. That’s green and free energy that really saves money on your bill.

Solar panel array in distance

b) Lower energy loss in cables or lower cost for purchasing cables.

Please remember Ohm’s law formula

V (Volts) = R (Ohm) x I (Amps)

Output power PO (Watts) = V (Volts) x I (Amps)

So

Resistance loss PR(Watts) = R (Ohm) x I2 (Amps)

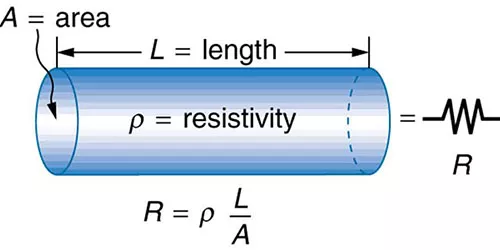

Then, if your PV panels are installed a long distance from your battery bank, the power loss of cable resistance is considerable ( PR = R x I2 ). Here R represents the resistance of cables. R increases as cable length increases:

Cable resistance formula

But if we double the Voltage of the solar array by wiring them in more series, according to PO = V x I, there is no change of total power outputPO , so the current through cable I should be half.

Finally, the resistance PR(Watts) = R (Ohm) x I2 (Amps) will be a quarter than before.

In fact, with MPPT, you could raise the voltage of the solar array even higher to reduce the current flow.

In this case, we increase the panel’s voltage to reduce the resistance loss through cables, and since we are using MPPT, which always tracks to harvest maximum power from panels, we have no voltage waste as PWM may have.

We could review this topic from another aspect. If you cannot raise the panels voltage, then you have to find out some solution to reduce cable resistance, as resistance = resistivity × length / area, it seems the only way is to use cables with large transverse areas, and that will be another huge sum of money to spend.

To recap, when it comes with small systems, PWM is a good solution since it is inexpensive, but for large systems, in order to improve conversion rates and not waste the solar panel capacity of harnessing solar energy, MPPT is preferable. MPPT would always be applied to higher power systems.

Learning knowledgeable information from the previous content is necessary before making the decision to purchase a solar charge controller for your PV system. A comparison table, listing the difference between PWM and MPPT, is also suggested. So, we put their pros and cons together to make it more convenient for you to review.

| Pros | Cons | |

| PWM | PWM technology has been available in PV systems for a long time and is a relatively stable and mature technologyThey are cost-effective and are affordable for most consumersPWM can withstand up to 60 amps load currentlyMost PWMs have a reasonable heat dissipation structure that allows them to work continuouslyPWM comes in different sizes to suit a wide range of applications | If PWM is applied to photovoltaic solar systems, the voltage of the solar panel has to match that of the battery bankThe current load capacity of a single PWM has not been developed and is still only up to 60 ampsSome smaller sized PWM charge controllers cannot be UL listed due to their poor structure designSome smaller sized PWM do not have fittings of conduitPWM has signal interference problems sometimes. The controllers generate noise in TV or radiosPWM limits the expansion of photovoltaic solar systems to some extentIt cannot be applied to high voltage off-grid solar arrays |

| MPPT | MPPT maximizes the conversion of solar energy from PV panels, and the rates can be 40% more efficient than PWMMPPT can be used in cases where the solar panel voltage is higher than the battery voltage.MPPT can withstand up to 80 amps load currentMPPT features longer warranties than PWMMPPT does not limit the expansion of solar panels in the systemMPPT is the only solution for a mixed solar power system | MPPT are more expensive than PWM. The pricing of some models is double that of a PWM charge controllerSince MPPT has more components and functions, its physical size is larger than PWM.MPPT are more complicated, so most time, we need to follow a guide when sizing the solar arrayMPPT solar controller constantly compels the solar panel array wired in strings |

The answer is no.

Generally, if your solar panel is less then 5 watts for every 100 amp hours battery, then you do not need a solar charge controller.

Here is a formula we can use:

Quotient = Battery Capacity (Amp Hour) / Imp of solar panel (Amps)

If the quotient is larger than 200, you don’t need a controller; otherwise, you’d better install a controller.

For example, if you have a 200AH battery and 20W panel, the quotient would be 200/1.18=169.5; in this case, you need a controller.

If you have 400AH battery and 10W panel, the quotient would be 400/0.59=677.9; in this case, you do not need a controller.

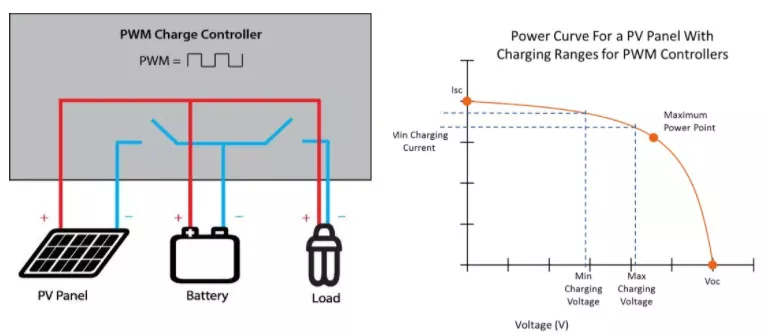

PWM stands for Pulse-Width Modulation. This comes into play when the batter bank is full. As it is charging, the solar charge controller lets in as much current as the PV panel can generate in order to achieve the target voltage for the charge stage of the controller. As the battery reaches its target voltage, the controller will then switch between the battery banks to the panel array. The battery bank will then be disconnected, which regulates the battery voltage and makes it constant. This quick switch method is called PWM, and what this does is it makes sure that your battery bank is charged while preventing the process of overcharging.

The PWM controller will usually operate slightly above the maximum power point. Figure shows the operating range for PWM controllers.

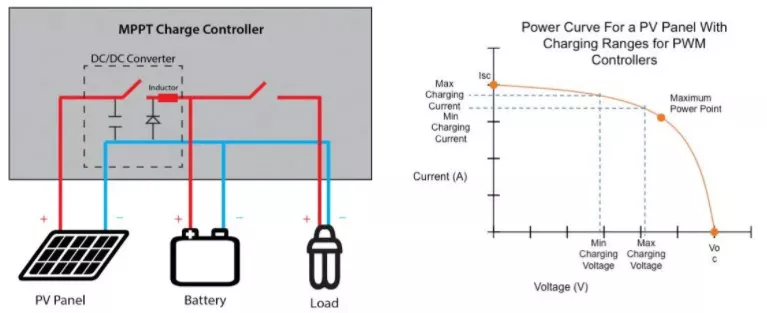

MPPT or the Maximum Power Point Tracking provides an indirect connection between the battery bank and the PV array. This indirect connection includes a DC/DC voltage converter that takes extra PV voltage and transforms it into an additional current at a lower voltage without necessarily losing power.

MPPT controllers are more costly than PWM controllers. However, the benefit to using MPPT is the fact that it is more efficient under particular conditions. If you want to purchase an MPPT, it would be better to check first if the professional function of the MPPT can be applied at the given site conditions. If you find out that there the MPPT’s functions aren’t applicable in your chosen site, then it would be more economical for you to choose the PWM controller.

MPPT controllers are able to pull this off because of an adaptive algorithm that follows the MPPT of the PV array, which then adjusts the incoming voltage in order to maintain the most efficient level of power for the system in place.

PWM Solar Charge Controller | MPPT Solar Charge Controller | |

| Array Voltage | PV array & battery voltages should match | PV array voltage can be higher than battery voltage |

| Battery Voltage | Operates at battery voltage so it performs well in warm temperatures and when the battery is almost full | Operates above battery voltage so it is can provide “boost” in cold temperatures and when the battery is low. |

| System Size | Typically recommended for use in smaller systems where MPPT benefits are minimal | ≈ 150W – 200W or higher to take advantage of MPPT benefits |

| Off-Grid or Grid-Tie | Must use off-grid PV modules typically with Vmp ≈ 17 to 18 Volts for every 12V nominal battery voltage | Enables the use of lower cost/grid-tie PV Modules helping bring down the overall PV system cost |

| Array Sizing Method | PV array sized in Amps (based on current produced when PV array is operating at battery voltage) | PV array sized in Watts (based on the Controller Max. Charging Current x Battery Voltage) |

Typical Applications of Led High Mast Light, High Mast Lighting Systems

View detailsSKD for Solar Street Lights; What is Solar Street Light Parts?

View detailsGuide to High Mast led lights, Why Choose our Led High Mast Lighting?

View detailsRemote Control User Manual of Solar Street Light, solar light remote controller

View details

HelloPlease log in